Fifty years. Half a century of innovation, determination, and unwavering commitment to the craft. As we celebrate Blasters’ 50th anniversary in 2025, we look back on a remarkable journey that began with one man’s vision and evolved into an industry-transforming legacy.

The Foundation Years (1975-1980)

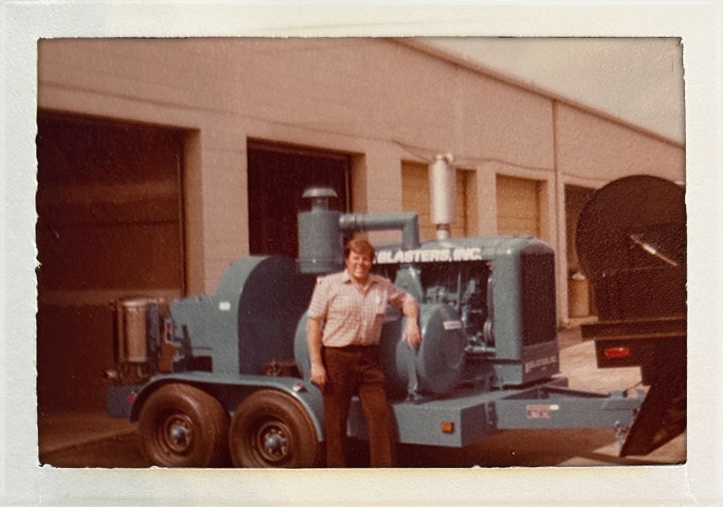

In 1975, Fred Boos started as a manufacturer’s representative for Partek-Butterworth-Gardner Denver water blasters, working primarily with power plants, sugar mills, and industrial facilities throughout the Southeast. But Fred was more than just a salesperson – he was a listener, a problem-solver, and a visionary.

When customers expressed concerns about expensive rental costs, Fred adapted. When they needed training and their operators left, he stepped in. When they required contractors, he became one. This customer-first philosophy became the DNA of everything Blasters would accomplish over the next five decades.

By 1980, Blasters had evolved beyond simple equipment sales. The company began offering rentals and contracting services while continuing the sales side of the business. That same year, Fred built the first warehouse and office facility in Tampa, Florida – the same location where Blasters continues to operate today, serving industries including shipyards and marine vessels, pool plastering and restoration, power plants and paper mills, phosphate and citrus industries, and specialized industrial cleaning applications.

Reaching for the Stars (Mid-1980s)

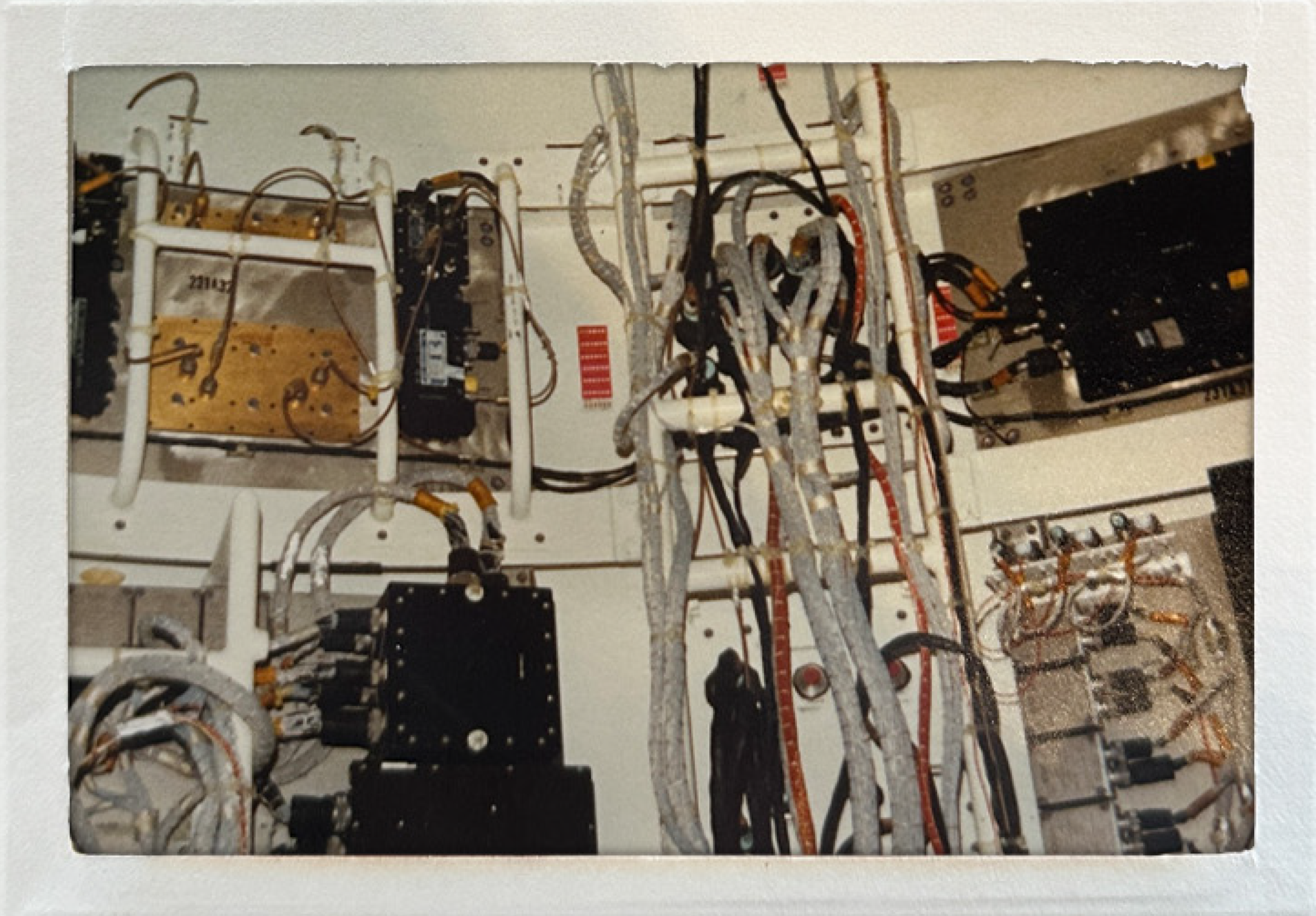

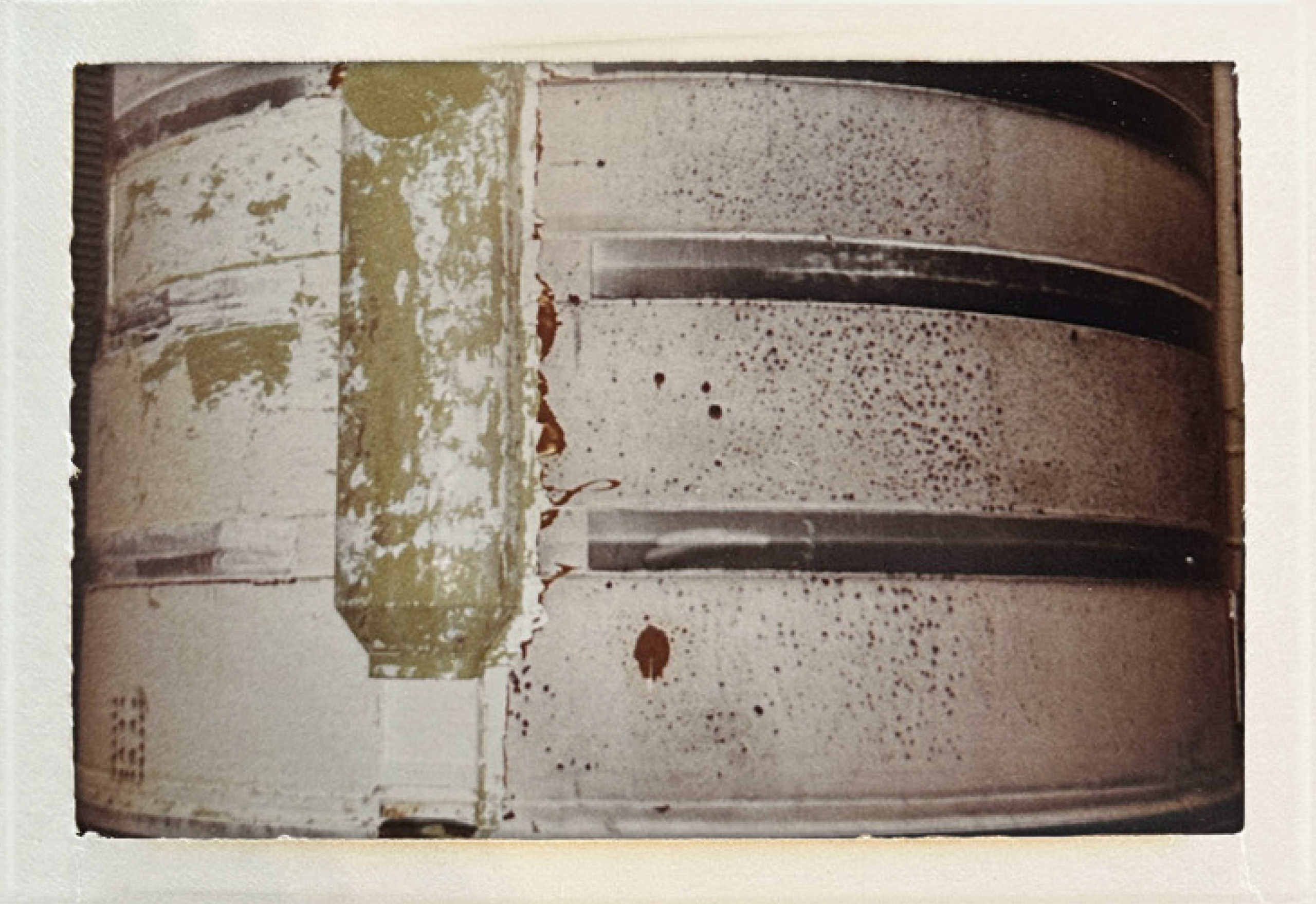

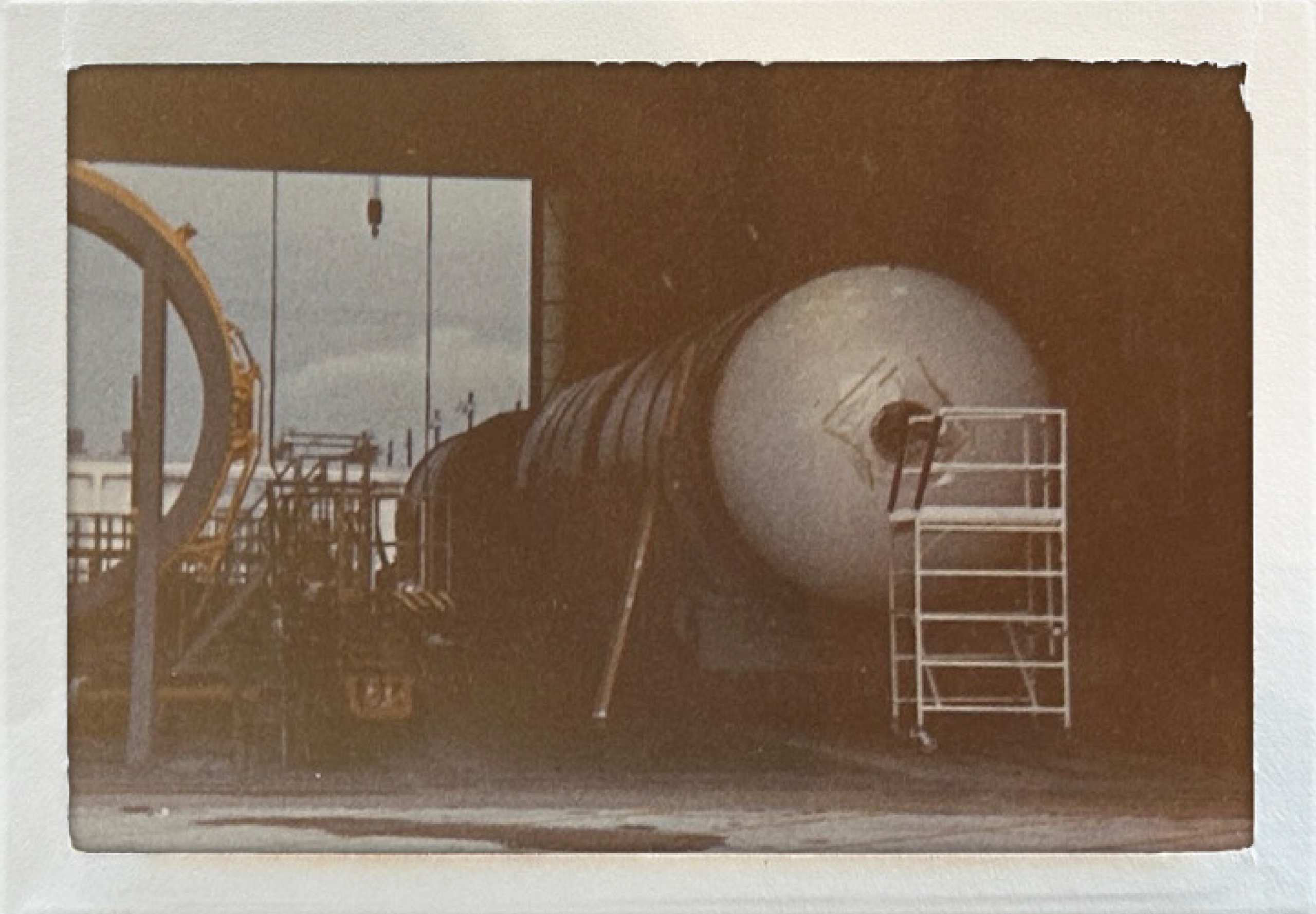

The mid-1980s marked Blasters’ entry into one of America’s most prestigious programs: the NASA Space Shuttle mission. Blasters became heavily involved in cleaning the solid rocket boosters after each launch and recovery, ensuring the safety and reliability of systems that carried astronauts to space.

This partnership with NASA represented more than just another contract – it was validation that Blasters’ precision waterblasting technology could meet the most demanding standards in the world. When America’s space program needed absolute precision and reliability, they turned to Blasters.

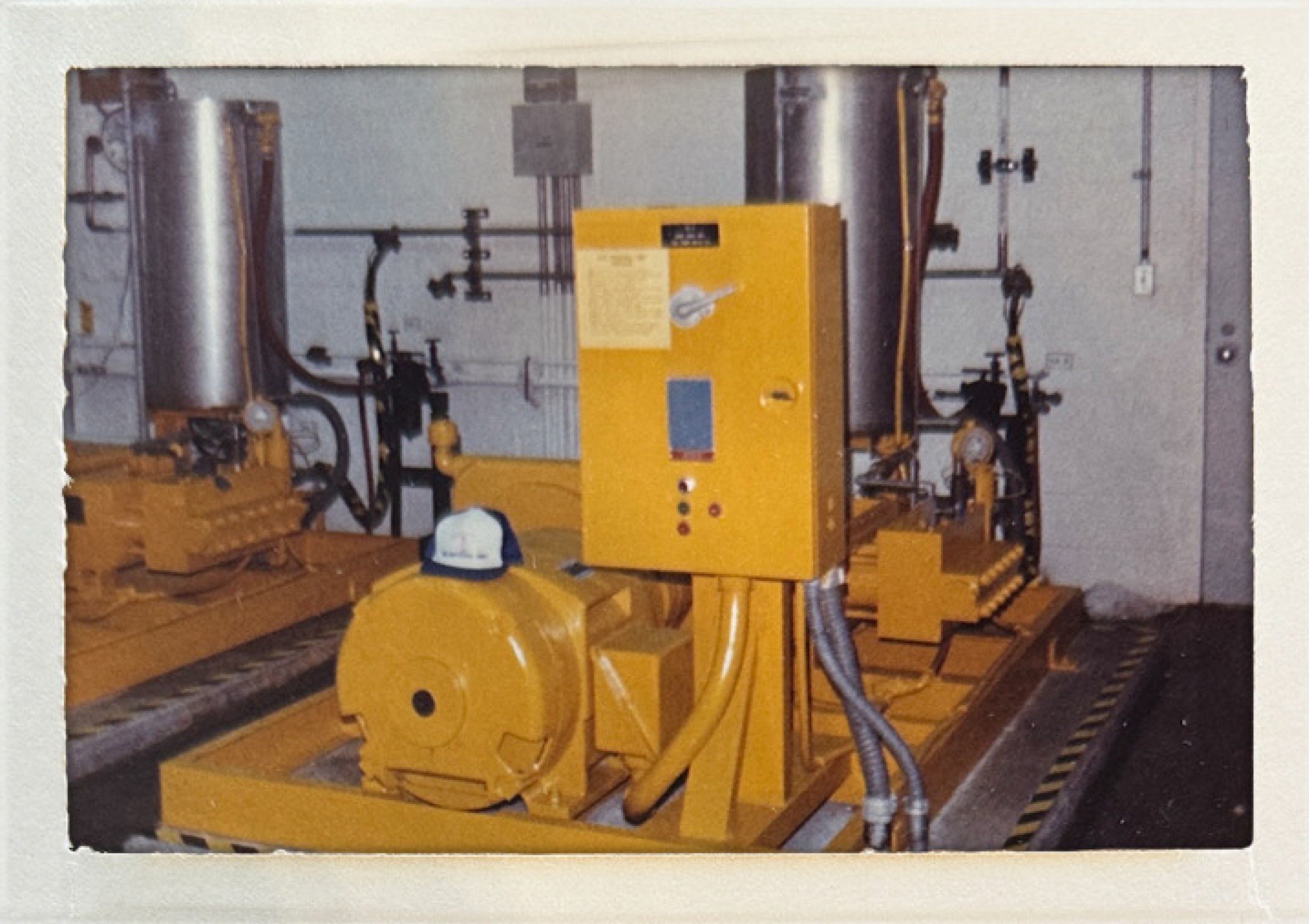

The Ultra-High Pressure Revolution (1990)

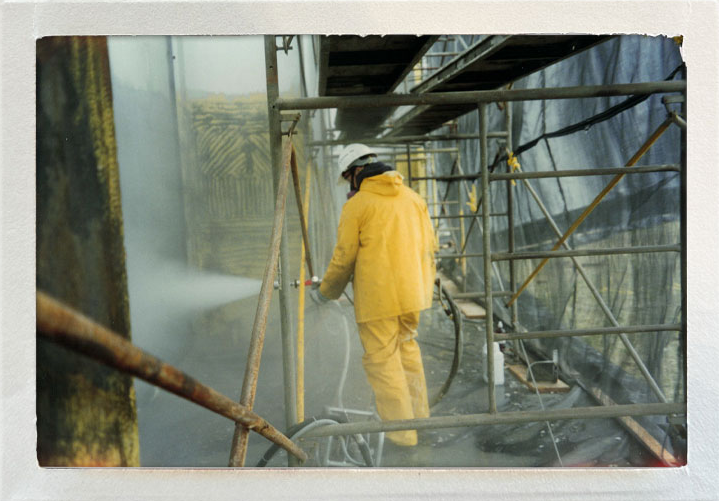

1990 marked a technological turning point as Blasters began ultra-high pressure operations at 35,000+ PSI. This wasn’t just an incremental improvement – it was a complete transformation of what waterblasting could achieve. Higher pressures meant more efficient cleaning, faster project completion, and the ability to tackle previously impossible jobs.

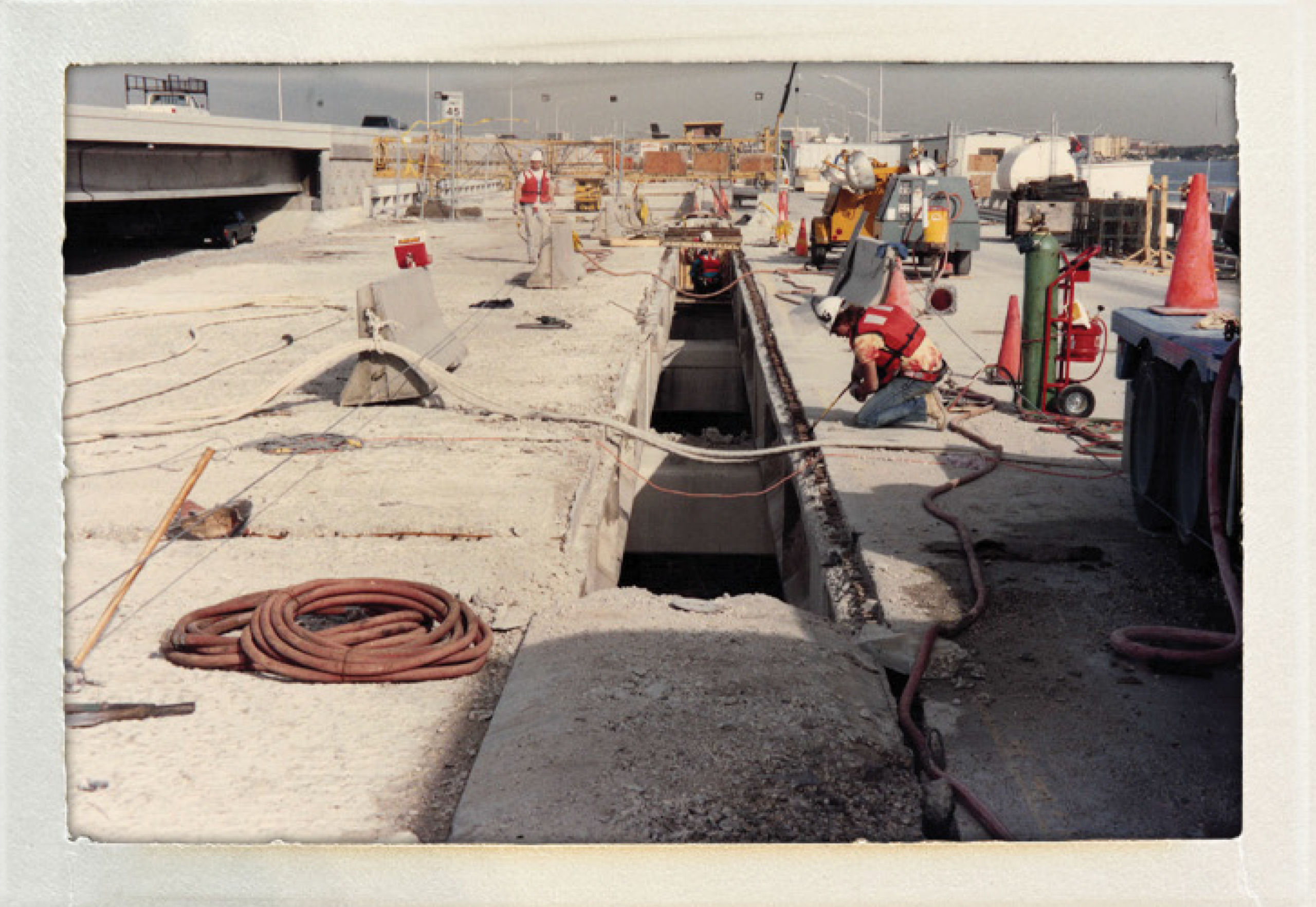

The Howard Franklin Bridge Breakthrough (1991-1992)

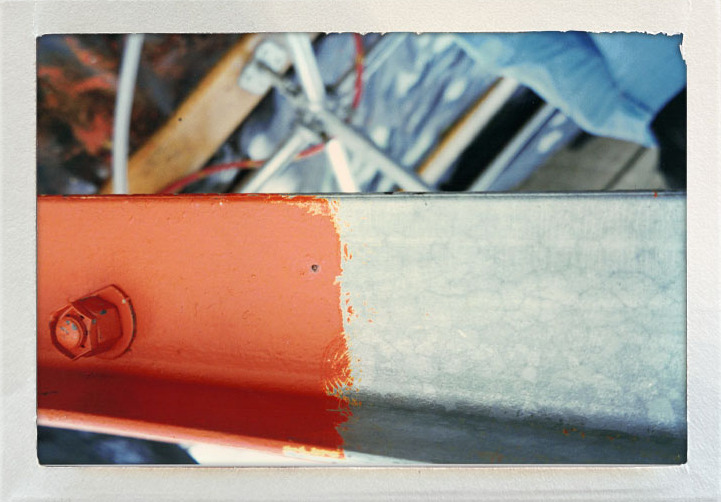

Every company has defining moments, and for Blasters, the Howard Franklin Bridge project was exactly that. This massive hydrodemolition contract involved over 1 million square feet of 2-inch concrete removal, including 16 miles of precision slots measuring 4×7 inches deep.

What made this project truly revolutionary wasn’t just its scope – it was how Blasters approached it. Rather than relying on existing technology, the company designed and manufactured custom hydrodemolition robots in-house. This innovation established Blasters as the industry leader in large-scale surface preparation and proved that thinking differently could change everything.

Innovation in Action (1993-1996)

1993 saw the birth of what would eventually become the Liquidator revolution. Blasters built its first stripe and rubber removal machine on a hydrostatically driven truck – the ARC (Airport Runway Cleaner). This groundbreaking machine proved that precision waterblasting could transform airport maintenance operations.

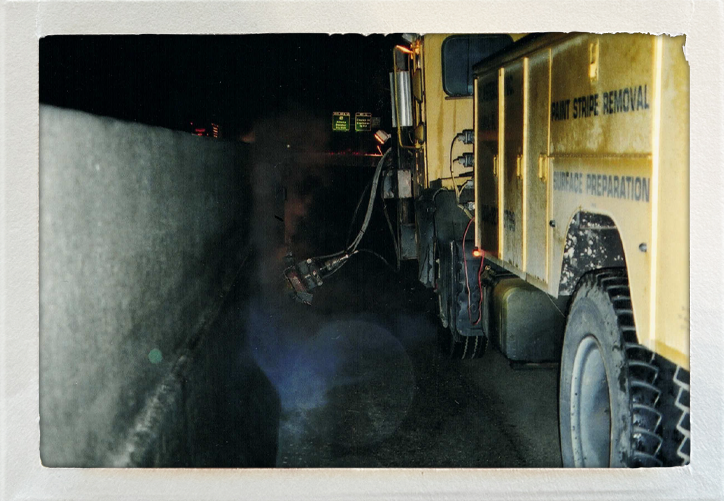

The innovation continued in 1996 when Atlanta prepared to host the Summer Olympics. Working with the City of Atlanta and Olympic Committee, Blasters cleaned the failing coatings from I-285 barrier walls using custom-designed robotic tooling at 40,000 PSI. With live traffic and the world watching, Blasters delivered flawless execution on the global stage.

Critical Infrastructure and National Security (1999-2001)

The late 1990s and early 2000s brought projects that highlighted Blasters’ role in national security infrastructure. The Atlanta Hartsfield Airport project with Peek Pavement Marking – internally called “Mission Possible” – involved converting a taxiway into an active runway, then back to permanent taxiway striping once a new runway was built.

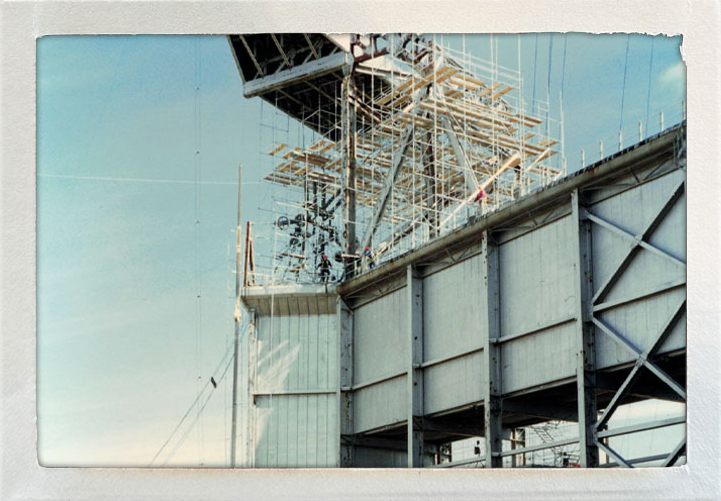

Another project of great significance was the Navy VLF towers project in Cutler, Maine (1999-2000). This massive undertaking involved 19 antenna towers ranging from 200 to 1000 feet tall – critical infrastructure for submarine communications worldwide. Blasters successfully completed lead abatement and removal while maintaining the highest safety and environmental standards.

In 2001, the company designed and manufactured a robotic waterblasting tool for removing coal tar epoxy with asbestos from live natural gas pipelines, showcasing the versatility and precision that had become Blasters’ trademark.

The Liquidator Era Begins (2000-2012)

The year 2000 marked Blasters’ first ATSSA trade show participation and the launch of the Eliminator – a ride-on Toro tractor system for stripe removal at 40,000 PSI. This wasn’t just another product launch; it was the beginning of an industry transformation.

The Eliminator evolved into the Kubota system in 2005, which added vacuum and recycle capability, and eventually became the truck-mounted Liquidator in 2012 with hydrostatic drive and vacuum systems. Each innovation built upon the last, creating a family of equipment that revolutionized airport and roadway maintenance worldwide.

Leadership Transition and Expansion (2003-2018)

2003 brought significant leadership changes as the company prepared for its next phase of growth. Scott Boos became President, Natalie Elliott became Vice President, and Fred Boos transitioned to CEO and Chairman, ensuring continuity while enabling fresh perspectives.

The company continued expanding its capabilities with the 2011 launch of Blasters Certified, offering refurbished water blasters through an extensive 147-point inspection process to markets throughout North America and globally.

Key team members joined during this period: Doug Elliott in 2012 with a focus on the Certified sales division, and Kristine Boos in 2017 as Director of Accounting and Finance. From 2013-2018, Blasters experienced substantial growth, expanding the Liquidator contracting truck fleet to five vehicles while significantly increasing manufacturing and sales operations.

The Modern Era and Beyond (2023-2025)

January 3, 2023, marked another significant milestone as Blasters sold all five divisions – Liquidator Manufacturing and Sales, Liquidator Contracting Roadway to Runway, Certified Used Waterblaster Sales, Parts and Accessory Sales, and the complete Rental division – to Federal Signal Corporation (Jetstream).

This transition ensured the continued growth and development of technologies that began in a Tampa warehouse nearly five decades earlier. Under the new partnership, 2023 saw the opening of FS Solutions Rental Center in Tampa and Blasters Liquidator joining the Sourcewell National Buying Cooperative.

Innovation continued with the 2024 launch of the high-production 15-gallon-per-minute Liquidator L4015 UVT stripe and rubber removal system, proving that five decades of experience continue to drive breakthrough technologies.

A Legacy of Innovation

As we celebrate 50 years of Blasters, we’re not just commemorating past achievements – we’re honoring a philosophy that started with Fred Boos in 1975: listen to your customers, understand their problems, and never stop innovating solutions.

From NASA space shuttles to Navy submarines, from Olympic infrastructure to daily airport operations, Blasters has consistently delivered precision waterblasting solutions for America’s most critical applications. The company that started in 1975 became an industry-defining innovator, creating technologies and methodologies that continue to shape waterblasting applications worldwide.

Fifty years of innovation. Fifty years of putting customers first. Here’s to the next chapter of waterblasting excellence.