From Roadway to Runway

A paint stripe and runway rubber removal system utilizing ultra high-pressure water equipment.

Runway, Roadway and Much More

Blasters Liquidator is a paint stripe and runway rubber removal system which utilizes ultra-high-pressure water equipment to safely remove roadway markings, airport runway markings and rubber buildup, curing compound, sealer and tack.

Roadway Marking Removal

Remove or rejuvenate pavement markings and retexture asphalt surfaces with full vacuum recovery.

Runway Rubber & Marking Removal

Remove airport runway rubber build up and runway and taxi-way pavement markings from both asphalt and concrete surfaces, with full vacuum recovery.

Curing Compound Removal

Remove curing compound prior to recoating, which is critical to the quality of coating bonding to new concrete.

Paint Cleaning & Rejuvenation

Clean existing striping/coatings to enhance coating reflectivity or to allow for restriping. Retexture asphalt surfaces to recover the profile in roadway tire tracks.

- Simplicity & Ease of Operation

- Competitively Priced

- Drastic Reduction in Operation Costs

- Best Run Time in the Industry

- Quicker Return on Investment

The Model Family

The Liquidator system is by far the most economical water-blast runway and pavement markings removal system on the market today. Both new and used units offer huge savings compared to the competition, with superior performance results.

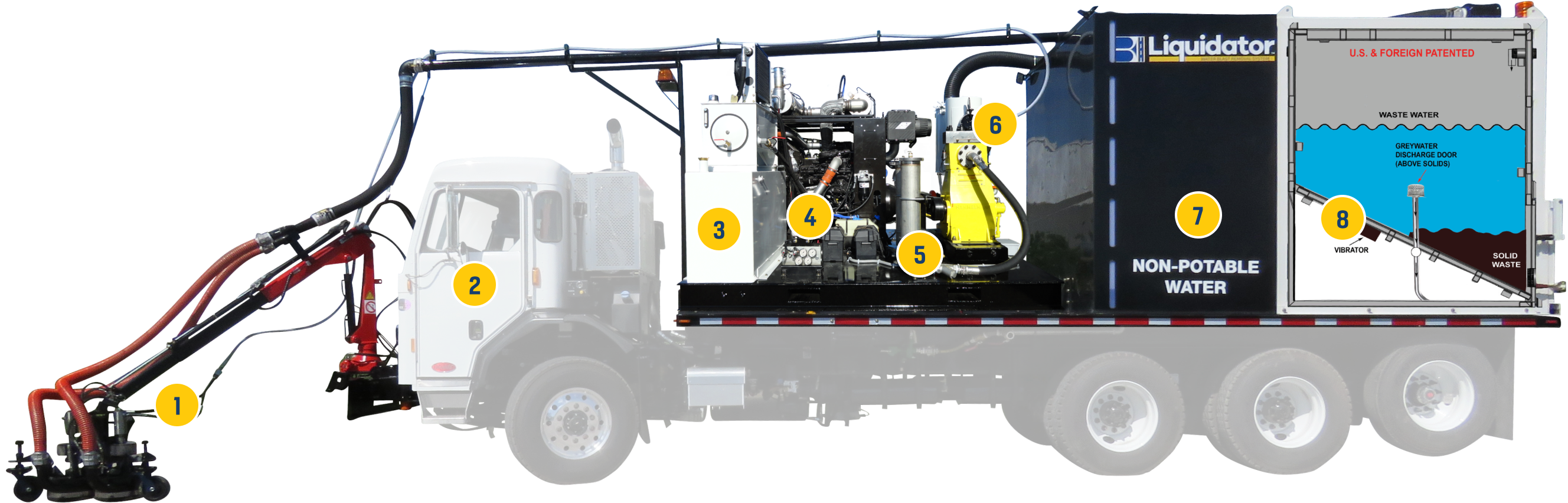

Dual or Single Head Assembly

48,000-66,000 GVWR (21,800-30,000kg)

Operates water boost pump, engages PTO, controls arm assembly and rotation of cleaning head.

275-430hp diesel engine. Low cost maintenance. Worldwide service through global network.

1,400 CFM (2,378 m³/hr) with filtration bag hose.

Jetstream pump / Hammelmann pump, 40,000 PSI @ 9-15 GPM (2,750 BAR @ 33-56.78 PM), Blaster filtration: 1 micron bag/cartridge filter.

1,500-3,250gal (5,678-12,302ltr). Custom built, lightweight welded poly. Low water level sight gauge.

1,600-2,250gal (6,000-8,437ltr). Steel construction with epoxy paint. Patented, slant floor design.

-

Utilization of 20,000 to 40,000 PSI (1,379-2,758 BAR)

-

Ranging from 7 to 18 GPM (26.50-45.42 LPM)

-

Vacuum available on all units

-

Integrated or Modular

-

11" and 36" cleaning heads (280-480mm)

-

All units have a 72" sweep function

Used Liquidators For Sale

Our Liquidator representatives can find you the best deal on a used Liquidator that fits your budget and needs. Let us do the hard work for you – Call us today!

- (813) 985-4500

Testimonials

Latest News

No job too big or too small

With the largest sole water blasting contracting fleet in North America, we know what it means to be prepared for a big job.

Two Customers Coming Together

Two of our Liquidator customers, Lincoln Airport with the assistance of Highway Signing, Inc. completed a large coating removal project at Lincoln Airport.

Touch Down!

Touch Down! The Liquidator team had a successful training at Lincoln airport with the delivery of our mid-size truck.

Inquire Below

Fill out the form below if you’d like to inquire about the Liquidator. We’ll reach back out to you once we receive your form submission.

"*" indicates required fields

Call Us

Prefer to get in touch directly? Call your Liquidator Representative today to discuss which truck is your best fit and help answer any questions.

Dennis Braswell

Vice President, Liquidator Sales & Contracting